From ‘Recyclable’ to ‘Recycled’: Process Innovation makes the Circular Economy Real

We’re out here chasing arrows, looking for resin identification codes, studying the recycle labels, and playing ‘match the opening’ on bins to dispose our trash. Why is recycling so hard?

You’ve seen the photos. Mountains of plastic trash on land; islands of plastic trash floating on the sea; wildlife encumbered by plastic; protestors calling for bans on plastics—and legislators listening and acting. On the other hand, plastics are incredibly useful polymers—strong, relatively light, and durable, they enable a world of life enhancing and life-saving applications. But the way we manage them now is garbage.

Less than 10% of plastics worldwide are recycled. Why is that so hard? Beyond the obvious needs to reduce, reuse, and then collect for recycle, the recycling process itself is difficult because there are a variety of plastics and (in general), they cannot be re-processed together.

A Primer on Plastics

‘Plastics’ refers to a number of materials, and what they all have in common is that they are human-made (there are no naturally occurring plastics) ‘chains’ of molecules linked together, and referred to as ‘polymers’. This is why many plastics—also knowns as plastic resin, or ‘resin’ for short—begin with “poly,” such as polyethylene, polystyrene, and polypropylene.

The various types of plastics exist because they fulfill unique needs depending on the application. Even for what would seem like a common application—packaging—many plastics are in play. For example, the kind of plastic for soda and water bottles—polyethylene terephthalate (PET)—has not been traditionally used for packaging things like laundry detergent or shampoo, which utilize high density polyethylene (HDPE) and then use polypropylene (PP) to create the cap and/or pour spout. Often the most efficient, least expensive way to create a bottle style package that is not for a beverage is to utilize a blow molded HDPE for the main body and injection molded PP to create the cap and/or pour spout. The material properties of these two types of resins make them the ideal choice for the various components – HDPE has a high strength-to-density ratio and is chemically inert, while PP can be injection molded at reasonable pressure and create strong hinges.

Recycling Realities

Packages and components made of different types of resin generally cannot be recycled as a single entity. Resins need to be separated by type to recycle. There are a couple of ways for this segregation to occur – separation by the consumer and/or separation at the recycling facility, with various sorting equipment such as near-infrared spectrometry, visual spectrometer, water baths, and more.

Packages often use different resins and combining resin types isn’t a problem in some cases but can become very problematic in other situations. For example, PET beverage bottles may have a cap made of polypropylene (PP), and when recycling these types of packages, the cap can be left on. The PET can be separated from the PP because there are density differences in these two resins and a simple water bath will separate various density resins (float or sink).

On the other hand, with packages like laundry detergent, shampoo, or similar bottles, the HDPE of the package body cannot be easily separated from the PP cap, because their densities are too similar and both resins float.

Another concern for recycling is color. For example, beverage bottles made of colored PET can be recycled, but it is usually not recycled back into its previous package type. PET bottles containing color are typically downcycled because color is difficult to remove from resin, and color segregation is difficult. Color segregation is typically limited to two color categories: natural/clear and color (which eventually becomes gray or black as a final color).

Rethinking Design

How do we improve the ability to recycle and ensure there is more recycled material with which to create future packages? It starts with design. There are various steps that brand owners can take to rethink their packaging and many of them have started to take steps to do just that.

For brands to truly realize a circular economy, they need to start treating their packaging as their own source of supply for recycled materials and designing their packaging accordingly.

In some situations, brand owners are moving away from single-use plastic packaging. There are many brands moving to refillable programs or exploring fiberboard packaging as alternatives to plastic, however both approaches also eventually require appropriate recycling or dispensation.

In other cases, removing color from plastic is a huge benefit for recycling but consumers may not recognize their favorite items on the store shelf. Large companies that are removing color are advertising these new and easier-to-recycle packages. Coca-Cola Company has changed ‘Sprite’ bottles from green to clear; Aldi requires clear plastic caps for milk tops.

Another promising approach is to create single-material packages to ensure recyclability. There are a few examples of this occurring already. Colgate toothpaste tubes and caps are both made of HDPE; Kellogg’s Bear Naked Granola is packaged in a polyethylene pouch.

As mentioned earlier, bottle type packages that contain both HDPE and PP have no easy way of being separated, especially when they are one unit. Until now, there was no seemingly feasible way to create high-performing, economical, single-material packages by either utilizing PP for the blow molded bottle or HDPE for the cap in these package types.

An Answer: Innovative Processing

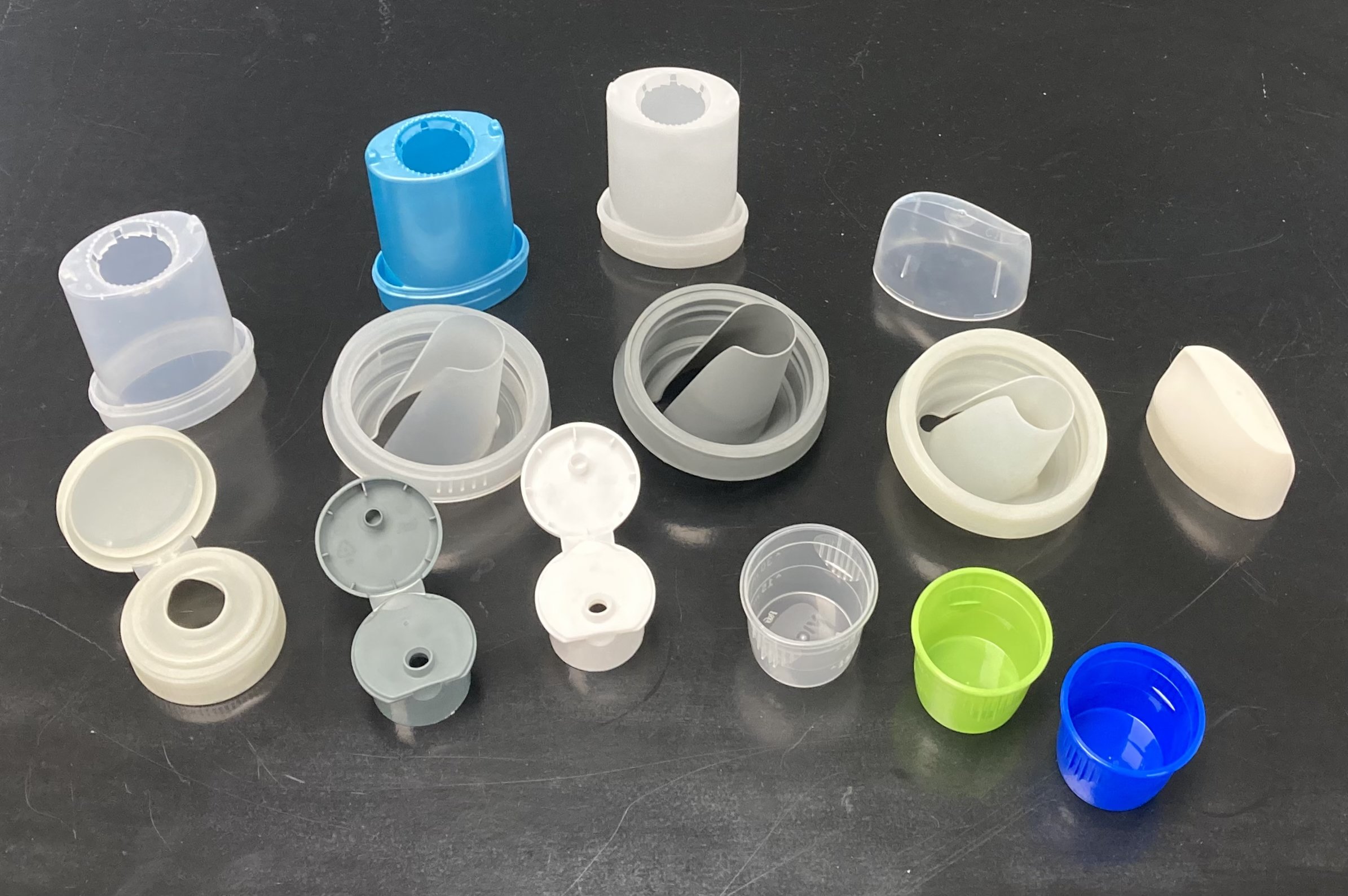

Using different materials in one package is not the only answer for cost-effective performance. Injection molding innovations, like iMFLUX, offer a unique platform where alternative materials can be used in typical PP injection molding applications. Because the iMFLUX system changes the way the injection molding machine operates, by lowering the pressure of the injection process, HDPE can now be used in applications where only PP could be used historically—and without changing out expensive molds.

Rethinking the possibilities when it comes to injection molding HDPE can be game changer for difficult-to-recycle packages, because once a package is made of a single material, it’s easy for the consumer to drop in the bin and the recycling facility to sort the object. In turn, this increases recycled material supply, feeding the original brand owner with more recycled supply.

There is no single answer to address the difficulties of reducing, reusing, and recycling plastics—but there is an array of possibilities that would allow us to continue to use enormously affordable, effective, and useful plastic resins in a way that is responsible—and that’s not just trash-talk.

Typical household items pictured here were traditionally made with virgin polypropylene (PP). In this photo, there are parts made from PP, polyethylene (PE), and recycled resin. Can you tell the difference? No? That’s the beauty of iMFLUX’s process innovation.

Photos by Nick Fewings and Nareeta Martin on Unsplash, and courtesy of iMFLUX, respectively.

About the author:

Kelly Santini

An advocate for environmental causes, Kelly Santini is leading the charge for injection molders to utilize iMFLUX to increase post-consumer resin (PCR) usage and work towards a truly circular economy for plastics. She received the prestigious Procter & Gamble CEO award in 2022, in recognition of the impact her work is having at iMFLUX, P&G and beyond. Prior to joining iMFLUX, she managed environmental, safety and health programs in a number of companies, including Lockheed Martin, The Coca-Cola Company and Novelis. Kelly earned her ‘Leading the Sustainability Transformation’ professional certification in 2020.

About iMFLUX:

iMFLUX, a wholly owned subsidiary of Procter & Gamble, is transforming the future of plastic injection molding. With iMFLUX, sites run more reliably with fewer operator adjustments. Manufacturers can produce higher quality parts, reduce costs, and lower capital—all while advancing sustainability efforts. iMFLUX provides the way to autonomous molding with a new capability to design and mold that impossible part. The revolutionary low-constant-pressure injection molding platform works with virtually any plastic injection machine, materials, and molds. For specific questions or more information, email info@imflux.com. Follow iMFLUX on Twitter at @iMFLUXinc or LinkedIn here.

Go back to the WholeWorks Connects blog page by clicking here.